Liebherr®

Applicable Platforms

-

R9200

-

R9250

-

R9350

-

R9400

Progress Mining’s ‘Series 1’ undercarriage product range has been developed to the latest OEM specifications and have been designed to be interchangeable with current OEM components. The range includes track shoes, drive sprockets, front idlers, bottom rollers, top rollers and fasteners.

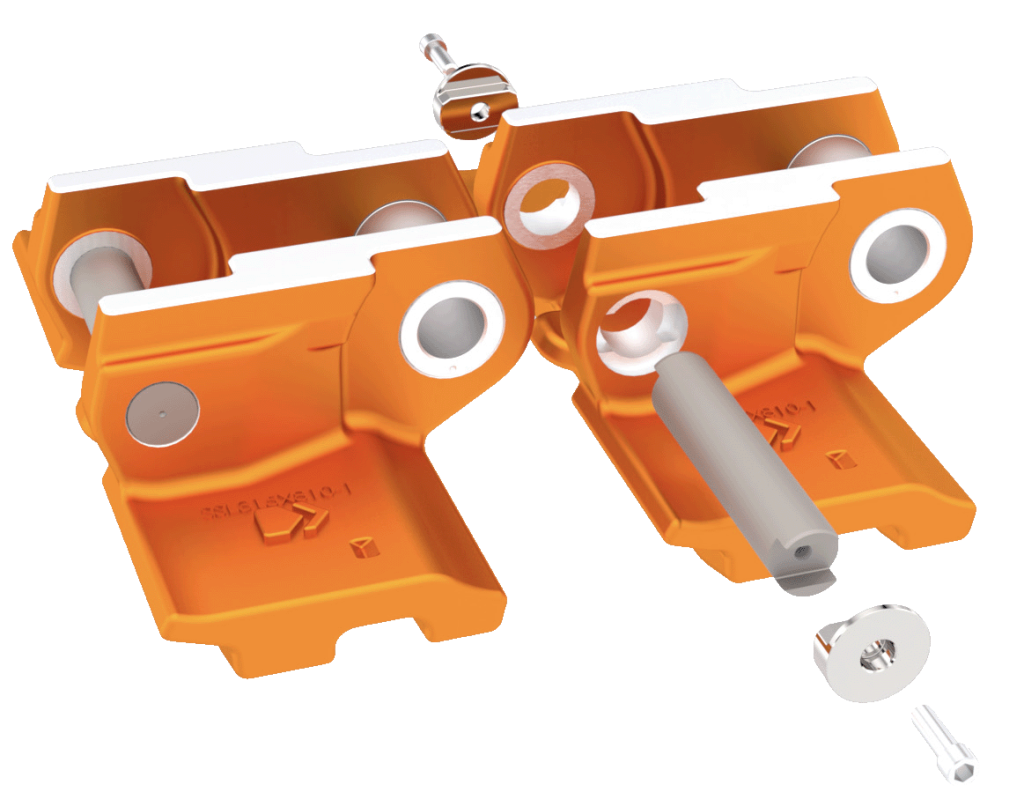

Track Shoe Links with innovative slip-fit master pin design

The chain link and bolt-on grouser pad has been replaced with a heavy-duty one-piece casting. The press-fit, high hardness, carburised and ground drive tube remains ensuring bore and drive lug wear performance. The chain link roller paths are induction hardened to maximise component life.

The ground press-fit connecting pins are induction hardened and include a ‘slip-fit’ master pin.

Replacing standard link designs requires large presses on site which introduces unnecessary risks, such as heavy lifting, falls and pinch points. This compromises the safety and efficiency of component change outs.

The Progress Mining slip fit master pin eliminates the requirement of a high force press when splitting the track belt on site, making the process faster, safer, cheaper and easier.

Liebherr® Link System Undercarriage Range

All components are produced to the highest standards in our factory in Europe.

Drive Sprockets

Roller Assemblies

Idler Assemblies

Also available is a full range of fasteners.

Contact us for any additional technical information or a customised quote.