Our Story

Don’t settle, move forward with the mining undercarriage experts.

With over a decade of design expertise and our own factory in Europe, Progress Mining is here to build on world best practices to set a new expectation in undercarriage performance, safety and running costs.

Small beginnings,

Large vision

Progress Mining was founded in 2020, the initial idea was to start with a 12-month pilot project to generate a basic product range, this would be used to test the market to see if there was space and demand for another aftermarket player. What started as an ambitious startup project soon gained momentum. Quite quickly it became apparent that owning the design, manufacturing and after-sales support process gave Progress Mining the flexibility and agility to get real world, workable results in relatively short time frames. The combination of decades of experience and an understanding of customer and market needs, meant Progress Mining could offer what was lacking in the market, providing high quality, precision engineered genuine undercarriage solutions, at a cost competitive rate in a timely manner.

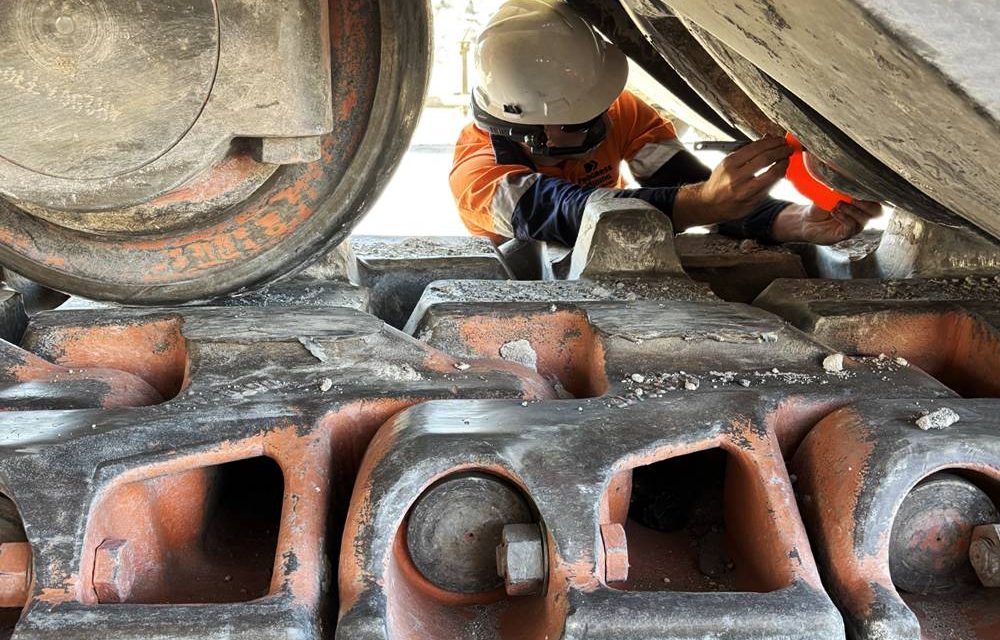

Building strong components through collaboration

Early on it became apparent that communicating with people on the ground was key. Their first-hand experience and knowledge of mine sites and machinery are a critical part of the puzzle, helping the Progress Mining team understand how undercarriage components and solutions can be made more efficient and cost effective. Progress Mining understood that machine and fleet condition monitoring are essential to get a full picture of how machines and fleets function, and where malfunctions and machine failures may occur. Before fitting an undercarriage to a machine on a mine site Progress Mining provides Condition Monitoring Services. By monitoring all vehicles in a fleet, the team can better understand which would benefit from an upgrade to a Progress Mining complete undercarriage solution. Only by fully understanding customer needs can Progress Mining provide a bespoke solution to their individual challenges providing superior products and service.

Manufacturing precision engineered results

The link between gathering information on the ground and transforming that into precision engineered solutions is vital to Progress Mining. The Australian based team of engineers work with the teams on the ground to analyse the data gathered to help expand the product range, working directly with the team in our European factory to get actionable results. Having direct control over the manufacturing process and supply chain is an important part of the Progress Mining product offering. Our customers are secure in the knowledge that there is no middle man and that their needs will be recognised and actioned in a timely manner. This direct link also facilitates Progress Mining’s future goal of becoming a complete undercarriage supplier. By investing in our manufacturing facilities and engineering capabilities we are working towards expanding our product range, developing side frames, car bodies, slew bearings and final drives. This goal will give our customers the ability to purchase a walk-in walk-out solution, giving them a sole provider and support for all their undercarriage requirements.

Global Reach

Progress Mining supplies undercarriage assemblies to mine sites across Africa, Asia, Australia, Canada, North America, South America and Europe.

Cost Competitive

Component interchangeability and superior warranty terms provides you with a genuine cost competitive alternative for your undercarriage needs.

Australian Design

All Progress Mining products are designed in Australia and produced in our ISO9001 certified European based factory.

Extended Part Life

Every purchase includes our Condition Monitoring Services. The data gathered allows us to support and advise our customers, helping to extend the life of your parts.