Innovation and customer support are the foundations of what we do at Progress Mining. A big part of how we achieve this is through our Condition Monitoring Service. Fleet condition monitoring allows our technicians to get a better understanding of how machines and components perform in different mine sites working with different types of materials. Most mines are very harsh working environments with rough terrain, mining hard and corrosive substances that can cause severe damage to excavator components. The team at Progress Mining perform Condition Monitoring inspections on fleets before and after our components are fitted to better understand our customers’ requirements.

In 2025, over 100 Condition Monitoring inspections were carried out at more than 25 different mine sites across the world. The value of the insights gained from these inspections is priceless, several innovations and product upgrades have been produced as a result:

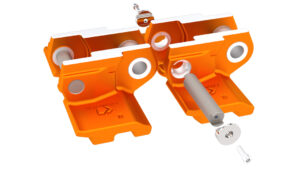

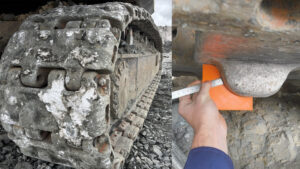

| Site inspections revealed that replacing standard link designs requires large presses on site which introduces unnecessary risks, such as heavy lifting, falls and pinch points. To resolve this problem the Track Shoe Links with slip-fit master pin design were created. This innovative design eliminates the requirement of a high force press when splitting the track belt on site, making the process faster, safer, cheaper and easier (Read More). |  |

| Heavy-duty track shoe design to suit Hitachi® EX2600 was developed to address component breakages at a lithium mine in Western Australia (Read Case Study). |  |

| Heavy-duty Link System designs created to suit Hitachi® EX1800 and EX1900, Komatsu® PC2000 and Liebherr® R9200, R9250, R9350, R9400 link system hydraulic excavator platforms. These new designs were created after observations at multiple mine sites that showed OEM link designs were not up to the heavy duty requirements (Read Case Study). |  |

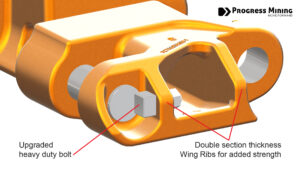

| Track shoe design upgrade for Caterpillar® 6030, 6040 & 6050/6060 undercarriages. Supporting ribs were added to the OEM design to strengthen the track shoe wings and prevent breakages caused by harsh operating conditions (Read Article). |  |

| New Liebherr R9600 platform release heavy-duty track shoe upgrade. After completing an inspection it was found that breakages were occurring at the retaining bolt area, compromising the integrity of the OEM track shoe design (Read Article). |  |

Our Condition Monitoring Service not only help drive innovation, they also help understand how long components last in specific working environments and conditions. This data and the reports generated help plan for servicing and replacement schedules, reducing machine down time and extend undercarriage life.

To find out how Progress Mining can become your go to vendor and to organise a Condition Monitoring Service for your fleet email us at info@progressmining.com