Collaboration is a key part of innovation and success at Progress Mining. Some customers gave us feedback on breakage issues they were having on Liebherr R9600 hydraulic excavator platforms with the OEM track shoe design. After completing an inspection as part of our condition monitoring service, we found that the retaining bolt area was where the breakages were occurring, compromising the integrity of the OEM track shoe design.

Above: Breakage on R9600 OEM track shoe design around the retaining bolt area indicated by the red arrows.

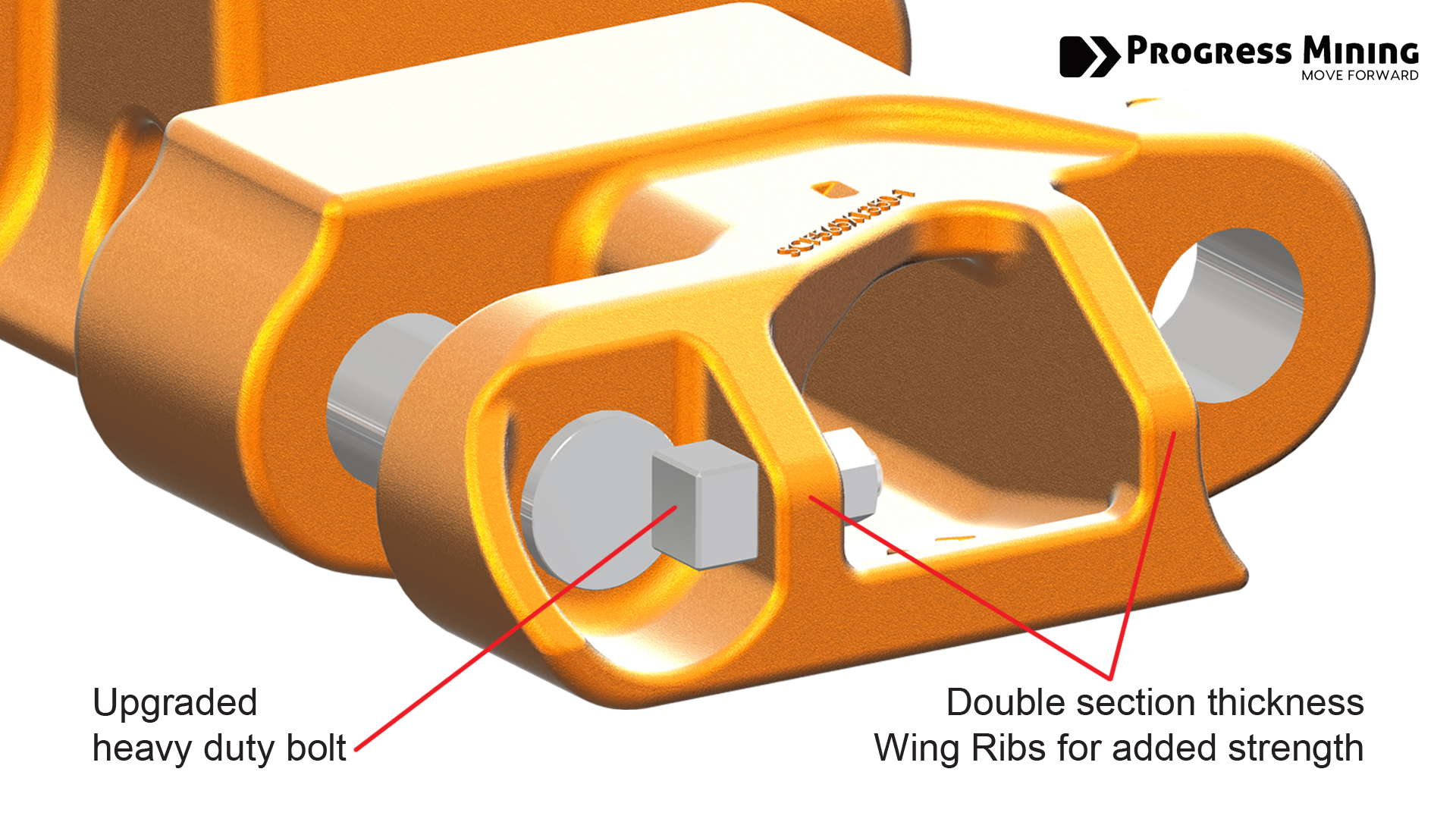

To help address these breakage issues, the Progress Mining engineering team upgraded our track shoe design to strengthen the problem area. This was achieved by doubling the minimum section thickness in these compromised areas. The standard retaining bolt has also been replaced with a more durable, heavy duty solid retaining bolt to add additional strength and durability. Combined, these changes will help prevent the wing ribs from being damaged and the bolt falling out from bucket strikes while the excavator is in operation.

Above: 3D render of Progress Mining’s new R9600 track shoe design with upgraded heavy duty bolt and double section thickness on wing ribs for extra strength and durability.

When comparing the 3D render of Progress Mining’s new design to the photograph above of the damaged track shoe, it is evident how additional material in this area will increase the durability of the track shoe and prevent critical material loss in this area. The Progress Mining R9600 track shoe is currently being developed and is due to be released in early 2026.

To get the latest updates on this project and to hear about others follow us on LinkedIn and YouTube or visit the News page on our website.